Filling Machines

Hot Filling

ENGINEERED FOR HOT-FILL

Full-Bottle Hot-Fill. Low Oxygen. High Hygiene.

-

Constant-flow, constant-pressure feeding with high-level tank — no foaming

-

Umbrella-flow sanitary valves · CIP-ready sealed product tank

-

Typical 1,000–36,000 BPH · 0.25–2.5 L heat-resistant PET

- 304/316 stainless steel rinse heads with water-inject spray design — cleaner, lower water use.

- Stainless grippers with protective pads reduce bottle damage.

- Durable 304/316 stainless washing pump.

Rinsing Section

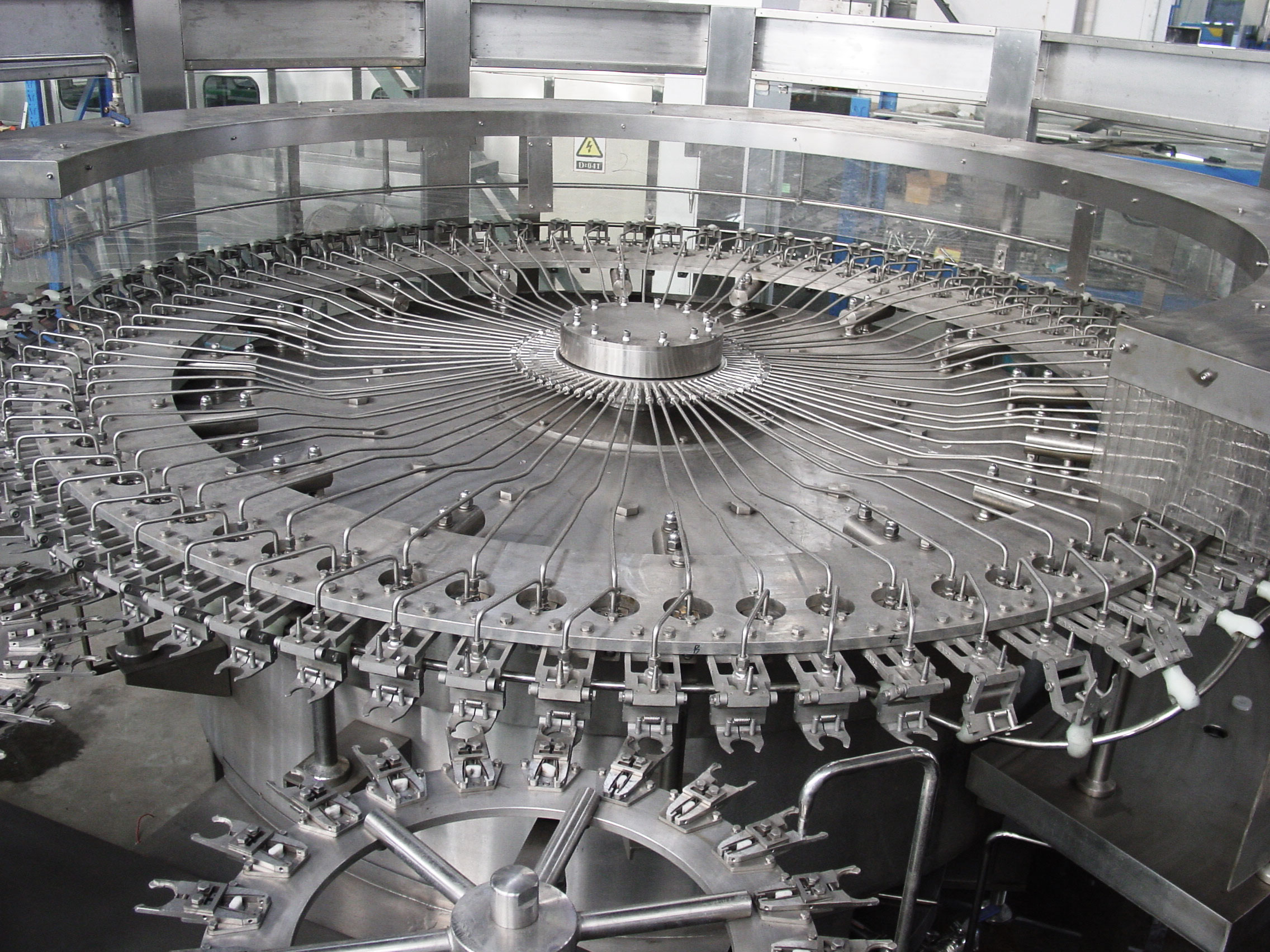

- 304/316 high-precision nozzles; consistent liquid level after filling.

- Fine adjustable filling volume; no dead corners; full CIP cleanability.

- 304/316 stainless filling pump and product-contact parts.

Filling Section

- Electromagnetic capping heads with torque control; place-and-cap design.

- No-bottle-no-cap safeguard; auto stop on bottle shortage.

- All 304/316 stainless steel construction for long service life.

Capping Section

BUILT FOR JUICE & TEA

- Hot Filling for PET Bottles

- Hot Filling for Juice With Plup

MACHINE MODELS

ASG RXGF Hot Filling Machine Specifications

| Model | Rinsing Heads | Filling Heads | Capping Heads | Capacity (BPH) | Machine Dimensions (mm) |

|---|---|---|---|---|---|

| RXGF14-12-5 | 14 | 12 | 5 | 4,000 | 2360×1770×2700 |

| RXGF16-16-5 | 16 | 16 | 5 | 6,000 | 2760×2060×2700 |

| RXGF24-24-8 | 24 | 24 | 8 | 8,000 | 2800×2230×2700 |

| RXGF32-32-8 | 32 | 32 | 8 | 12,000 | 3550×2650×2700 |

| RXGF40-40-10 | 40 | 40 | 10 | 15,000 | 4360×3300×2700 |

| RXGF50-50-12 | 50 | 50 | 12 | 18,000 | 4720×3550×2700 |

| RXGF72-72-18 | 72 | 72 | 18 | 32,000 | 6120×4650×2700 |

| RXGF80-80-20 | 80 | 80 | 20 | 36,000 | 8090×6430×2700 |

- Full-bottle hot filling prevents post-cooling collapse and minimizes dissolved oxygen.

- Optimized product feeding — constant flow & pressure with foam-free high-level tank design.

- Advanced product tank — sealed, vented, temperature-monitored; distributor replaces bulky bowls on higher speeds for CIP pressure cleaning.

- Hygienic umbrella-flow filling valves ensure fast, sanitary filling.

- Precision temperature control dedicated for hot-fill stability.

- Automatic recirculation tank for product return and smooth start-up.

- Complete CIP system for thorough internal cleaning.

HOT-FILL WITH PULP

ASG Automatic Juice with Pulp Hot Filling Machine

-

Wide Application – Hot-fill fruit juice, tea, and functional beverages into heat-resistant PET or glass bottles (0.25–2.5 L).

-

Flexible Capacity – Production range from 1,000 to 36,000 BPH, easily scalable for both PET and glass bottle lines.

-

Pulp Filling Precision – Piston-type pulp filler separates solids from juice, preserving fruit pieces while preventing clogging.

-

High-Accuracy Filling – Stainless steel nozzles with fine-adjustable volume ensure consistent liquid levels.

-

Hygienic Design – All contact parts are SUS304/316, with polished surfaces and no dead corners, fully CIP-cleanable.

-

Trusted Components – Key electricals from Mitsubishi, Omron, Siemens guarantee stable, global-standard performance.

-

Complete Solutions – ASG provides turnkey beverage lines for PET and glass bottles, covering blowing, filling, and packing.

Contact